Serial Numbers, Lots, and Expiration Dates

PULPO WMS empowers you to decide the extent of details you leverage for managing your warehouse. Regardless of your choice, PULPO WMS guarantees optimal organization of your inventory in the appropriate locations.

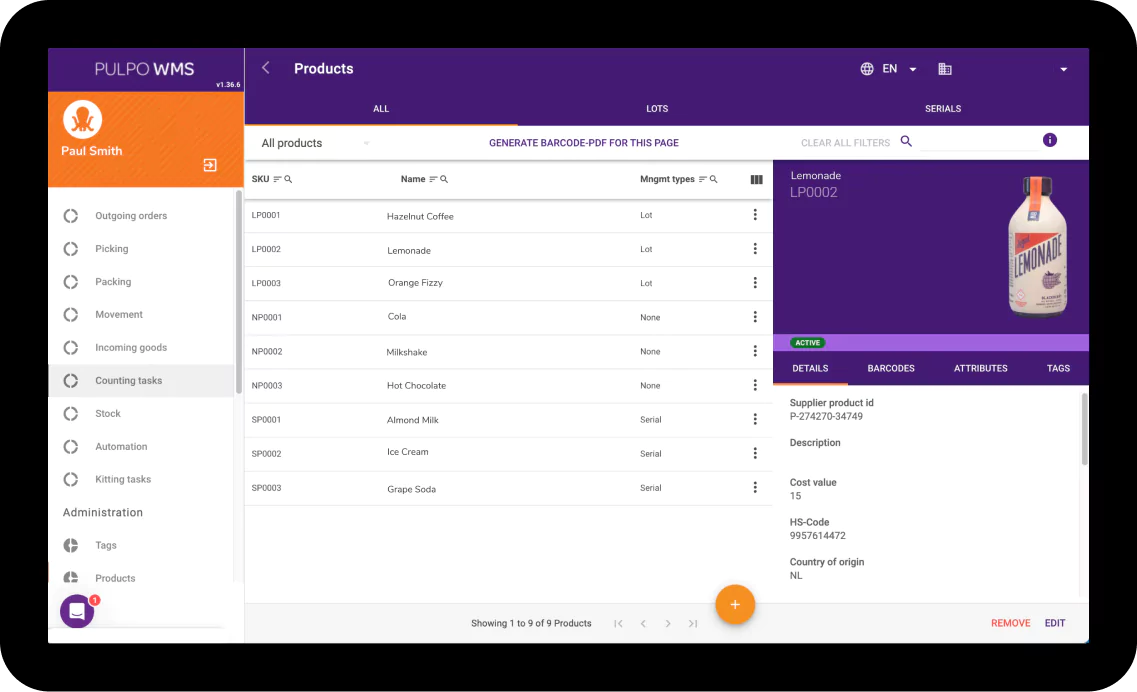

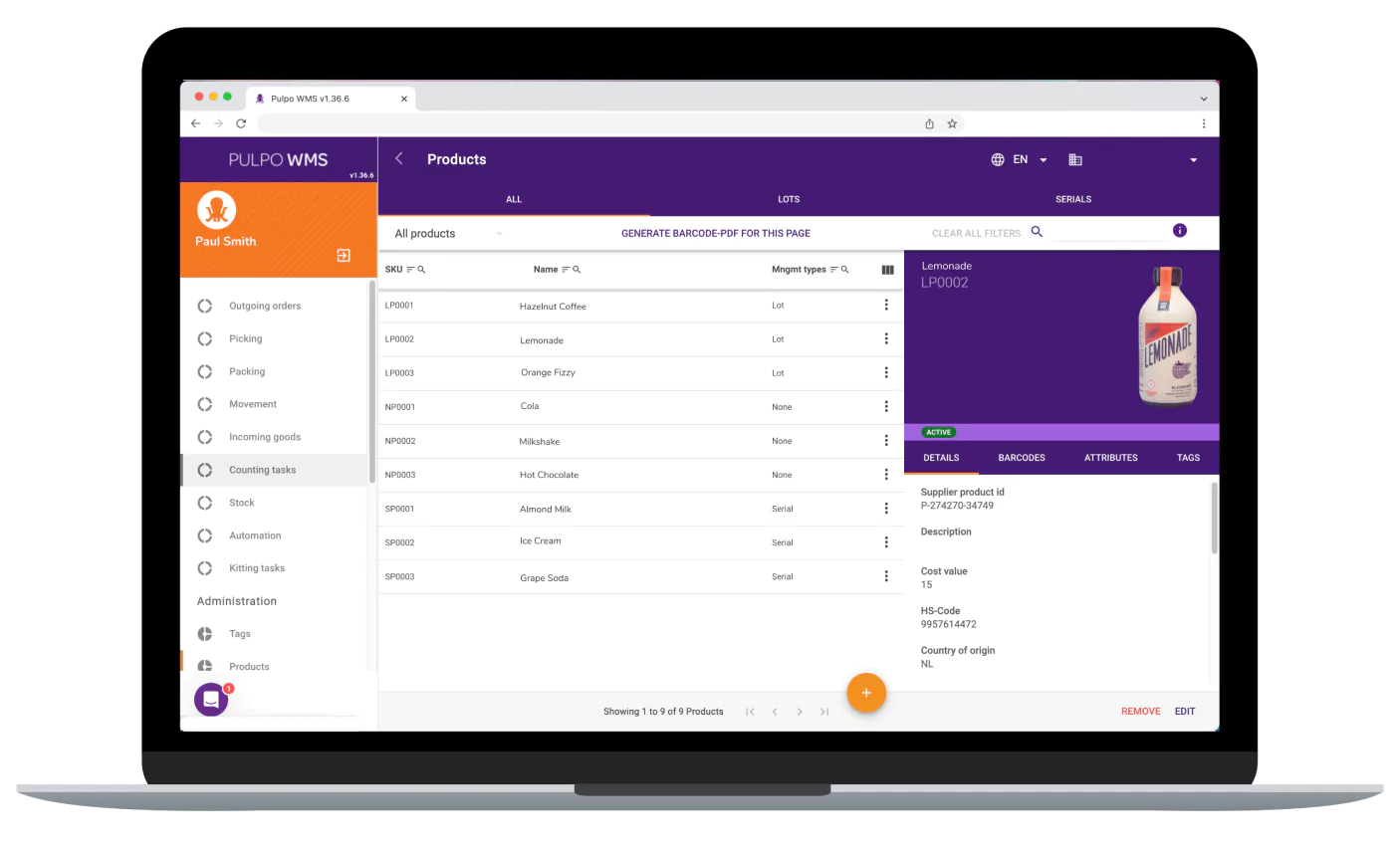

Handling of product types in PULPO WMS

Intelligent warehouse strategies

The PULPO WMS ensures optimal and traceable life cycles in the warehouse for all types of products. The system guides employees to the position of the product with the shortest expiration date and indicates which lot to pick, minimizing errors and product losses.

Products are synced from third-party systems, and PULPO WMS can be used as the leading system for product information. Products can have additional attributes and types, which can be imported from third-party systems and used to control automatisms in processes.

Standard Products

Products that have a uniform SKU barcode for identification. Rules such as FIFO can be applied here.

Lot number products

Perishable products typically come with a production lot number and a best-before or expiration date. At PULPO WMS, our customers commonly employ the first-expired, first-out (FEFO) method to manage these products.

Products with serial numbers

Products with serial numbers usually have a high value and come with a warranty. Here it is important that it is always transparent which product was sent to which customer.

Products with lot numbers

Expiration date and traceability

FEFO: First Expire - First out.

Products with lots and best before date (BBD) / expiry date require special handling. PULPO WMS ensures by default that products with the shortest expiry date leave the warehouse first.

If a customer has special needs (e.g. expiry date in 365 days at the earliest), this can be easily taken over from the leading system when creating the order or administered directly in PULPO WMS.

Lot tracing can be relevant for quality purposes as well as legal requirements.

✅ Keep products fresh and safe for your customers

✅ Proactive sell-off or elimination of expired products

✅ No manual monitoring through inventory tasks

Serial numbers

Serialization and transparency

Warranty processing and quality control

Products with serial numbers have individual numbers for each product. Since these products are usually of higher value or offer warranty, it is important to document the serial numbers.

If a customer receives specific serial number(s) in his shipment, this can be easily taken over from the leading system when creating the order or administered directly in PULPO WMS.

✅ Prevent fraud by documenting sold serial numbers.

✅ Facilitate warranty cases with your suppliers.

✅ Sorting out defective goods with the help of serial numbers.

Advantages of PULPO WMS

PULPO WMS simplifies warehouse management. The user interface is intuitively designed and to the point. Synchronize your products and data fields such as item number, name, description, weight, price and supplier with PULPO WMS and benefit from the advanced features of PULPO WMS.

✅ Latest technology standards ensure maximum innovative strength.

✅ Best-in-class usability facilitates rollout and onboarding for warehouse employees.

✅ Open API and standard integrations enable implementation in just a few days.