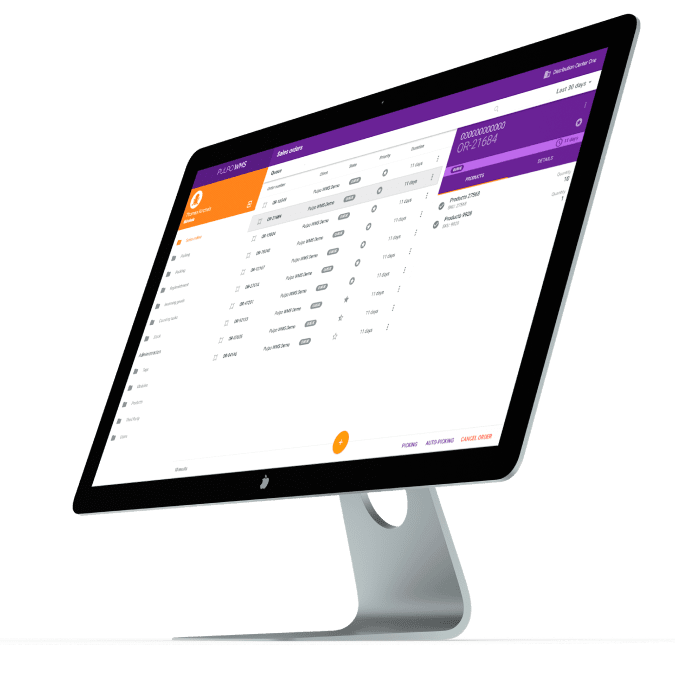

Advanced Picking Methods with PULPO WMS

With PULPO WMS, you define individually for each order which picking method your employees should use. PULPO WMS then calculates the optimal picking route, according to your predefined rules, without any further action on your part.

Picking Strategies

Paperless Advantages

Optimization for a labour intensive process

Deciding which picking method to use in your business is not always easy. However, with a smart choice, deliveries will be shipped much faster and customers will be completely satisfied. Alternatively, a picking method that lacks efficiency and accuracy, or is simply unsuitable for a particular type of order, can land a company in financial trouble. PULPO WMS always guides your employees through orders via the shortest routes, regardless of the picking method.

Step-By-Step

One for All

All for One

Cluster Picking

High productivity gains

For high order volumes per day

Similar to batch picking, this method combines several orders in a picking task. Additionally, PULPO WMS helps warehouse staff pre-sort the products into ordered containers during the picking process.

✅ Can unburden your employees in the packing area.

✅ Your pickers can keep better track of your orders.

Cross-Docking

Fast Goods-In and Goods-Out

Increase Just-In-Time Sales

Cross-docking is a special form of order picking. An incoming product will be received in PULPO WMS directly and placed in a temporary cross-docking position. From there, the goods are then picked and taken to the packing station, without the article going through the warehousing process.

✅ Can massively shorten the lead time of JIT orders.

✅ Reduces the administrative burden of JIT jobs.

Additional Benefits

Enterprise Level Functionalities

More optimization and automation

In addition to advanced picking methods, many top-tier functionalities can be achieved with PULPO WMS.

✅ Automatic picking-task generation.

✅ Prioritization of outgoing orders.

✅ Sort articles in picking lists by the shortest route.

✅ Permission-based picking rules. Link user capabilities

like forklift driving to heavy goods.

Get in touch and start optimizing your warehouse with pick and pack software

Ready to boost your E-Commerce profitability?

Learn how PULPO WMS automates your logistics, enhances your warehouse management and optimize your operating costs, enabling your business to scale-up